Accelerating Artificial Intelligence in Asset Management – Part II

In our last Blog post, the sport of Formula One racing was used by comparison to describe some of the challenges of implementing AI. This post continues with that theme to discuss the approach Itus Digital is taking to address some of those challenges.

A key challenge for AI technology in asset management is the complexity of using it unless you are a data scientist or programmer. How do organizations take advanced technology, like AI, and make it available and easy to use for those who could drive the most benefit with it? The front-line team, operating and maintaining the plant, have the knowledge and expertise to make a risk vs. cost tradeoff decision to deliver operational results. AI is a supporting technology that should be used primarily to enable teams to be more productive and efficient in their daily roles instead of being overwhelmingly complex and hard to use.

Would you really trust the Pit Crew to control the steering wheel of a Formula One Car? Of course not. Their role is to support and enable the drivers to be as efficient and productive as possible. The Itus Digital solution provides a way to visually model patterns or anomalies in machine data. The key word is visually. This approach allows an engineer, who “knows” the asset operating conditions and failure risks to build models based on the variances that occur from those conditions.

Using the comparison to Formula One, the F1 driver, from their cockpit, sees a condition they want to use as a data point. The driver can “mark” the track by pressing a button on their steering wheel. For example, the driver might want to associate this data point (or section of the racetrack) with performance data involving braking power, or cornering. The F1 team uses the data that’s collected to adjust their race strategy to achieve incremental performance improvements.

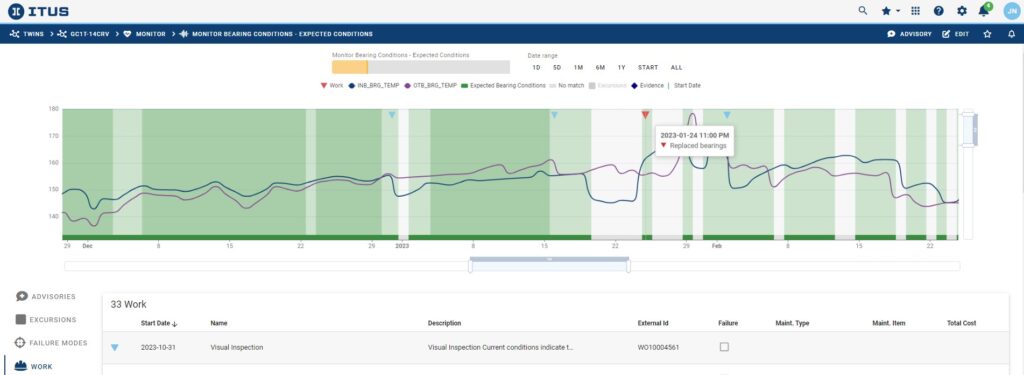

Our visual approach uses the engineer’s expertise and enables them to observe, and “mark” data variances which indicate emerging risk of failure, deviations which could affect quality or even expected operating conditions.

The process starts with the engineer evaluating the historical data for the machine to supply context for modeling the asset. Information such as work performed, identified failures, process and machine condition are brought together in a timeline view. With one complete view of the machine’s behaviors and activities, engineers can identify “markers on the track” so that specific areas of improvement can be found and encapsulated in a machine learning model.

But what if you only know what ‘good’ conditions look like for a machine and aren’t entirely sure how to pinpoint ‘bad’ anomalies or conditions? Many AI techniques focus on historical behaviors which are precursors to ‘bad’ conditions where the machine is likely to fail. These ‘bad’ conditions can be highly erratic and may not look the same every time. So how do you help the reliability engineer that only knows what good operational conditions look like and simply wants to be notified if there are deviations from that?

The Itus Digital approach allows its users to visually model ‘good’ conditions where equipment is running as expected and send notifications when deviations from those conditions are detected. This solution is a great starting point for organizations which may not have exact tracking of historical failures but look to know when key operating parameters show potential machine issues.

There are still many mysteries surrounding AI, but we are simplifying the on-track experience for our drivers, the engineers, so they can spend their time solving problems, improve the quality of their decisions and accelerate their asset management maturity.