How Asset Twins™ boost Asset Performance Management

What is an Asset Twin™

The term “digital twin” is seemingly used today to cover any possible use case where there is a digital representation of a physical object. In the industrial space alone the term is used to describe digital capabilities which can include 3D modeling, virtualization, augmented reality, and machine learning analytics. For the management of industrial assets, the term Asset Twins™ better describes the overall strategy and plan to optimize the performance of assets over its lifespan. As a digital, virtual representation of a physical asset, the Asset Twin includes:

- Design characteristics

- Failure Modes and consequences to the business

- Expected mission time

- Preventative Maintenance Plan

- Inspection & Monitoring Plan

- Historical failure rates and costs

More importantly, it defines the key components for maintenance, reliability, production, and operations professionals to manage the asset strategy and monitor asset performance in the context of its use. Going one step further, asset twins constantly assess failure risk, proactively identify emerging threats and automatically prescribe corrective actions.

An Asset Twin focuses on operationalizing your asset strategy, both in terms of monitored conditions and activities performed. It brings your asset strategy (or maintenance tactics) together seamlessly with asset health monitoring of conditions and allows you to strategically manage industrial assets to ensure optimal performance at an ideal cost profile.

The Itus Digital Asset Twin Technology

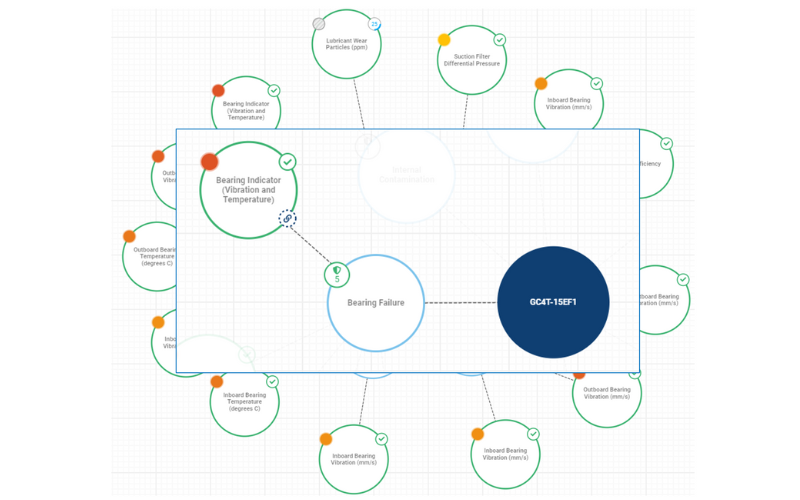

Our Asset Twin actively monitors the asset and advises you of emerging failure risk and associated business consequences through three core constructs:

- The Asset and its business objectives. We start with the virtual definition of the Asset and provide a classification, mission time, and typical failure rate. Armed with this knowledge, you can assess the overall failure risk in the context of operational consequences. Further, you can gauge the financial impact of the potential failure in terms of lost production, repairs, and other costs.

- Dominant Failure Modes that point to the asset’s vulnerabilities. Our technology provides a definition of dominant Failure Mode definitions for the asset and presents it clearly and straightforwardly. Also, for each Failure Mode, it gives the best approach to mitigate the failure risk. By defining the conditions to monitor and best maintenance activities, you can protect the asset and extend its value and lifecycle.

- Protections employed to guard against the failure modes occurring unexpectedly. Protections are more than just a statement of intent to perform an activity or collect data; they are essentially the operationalization of the strategy. Protections include active monitoring of data with analytics that trigger prescriptive and proactive action to mitigate emerging threats. Two primary forms of protection can manage failure risk: condition-based and activity-based.

Together, the (1) Asset, (2) Failure Modes, and (3) Protections provide an active digital model of current condition, risk, and prescriptive remediation as needed. This Asset Twin provides the “operationalization” of the asset strategy to ensure business objectives are not interrupted. It virtually models your asset, improves equipment performance, and optimizes maintenance without the cost and complexity associated with a Digital Twin. We based our approach on core reliability engineering principles that our platform applies to assets across all levels of criticality and consumable by industrial organizations of all sizes and maturity.

Learn more about how Asset Twins drive the management of Asset Strategies.

.