Rapid Compliance to ISO 10816 Vibration Monitoring Standard

Vibration data expansion and standards adoption

The industrial market has exploded with new sensors and solutions which can quickly and affordably monitor vibration in rotating machinery and predict potential failure. From wireless sensors to handheld devices to completely outsourced condition monitoring services, you now have many options when looking to mitigate one of the most common failure risks in rotating machinery, high vibration.

In addition, we are seeing industrial organizations increase their adoption of standards as they can provide reliability and maintenance teams with the opportunity to take advantage of expert perspectives and years of learning at a very low cost. These technical standards, in particular, provide a solid starting point for organizations looking to implement basic condition monitoring.

As a technology provider to the industrial market, Itus Digital leverages standards as they allow our customers to quickly develop best practices built on what experts across industrial sectors, have developed over the years. Our latest work here is the inclusion of ISO 10816 compliance elements into the Itus Asset Twin Library.

This article offers insights into the ISO 10816 Standard and provides a walk through on how Itus Asset Twin capabilities enable the requirements of this standard. As a technical footnote to this article, we will limit our discussion to the use of overall vibration readings as defined in the ISO Standard. We will not be addressing the use of detailed vibration data (such as waveform) which are also a key aspect of vibration data diagnostic activities.

What is the ISO 10816 Standard?

The ISO 10816 standard provides guidelines to evaluate the severity of overall vibration levels of machinery taken from sensors or handheld devices. The standard has seven ‘parts’ which offer guidance for a variety of machine designs and applications. For the audience reading this blog, ISO 10816-3 (Part 3) will be of particular interest as it specifically applies to industrial machines with nominal power above 15kW and speeds between 120 and 15,000 revolutions per minute (RPM). Typical machines included in this standard include pumps, fans, motors, blowers, and rotary compressors which can often be significant drivers of repair cost and downtime.

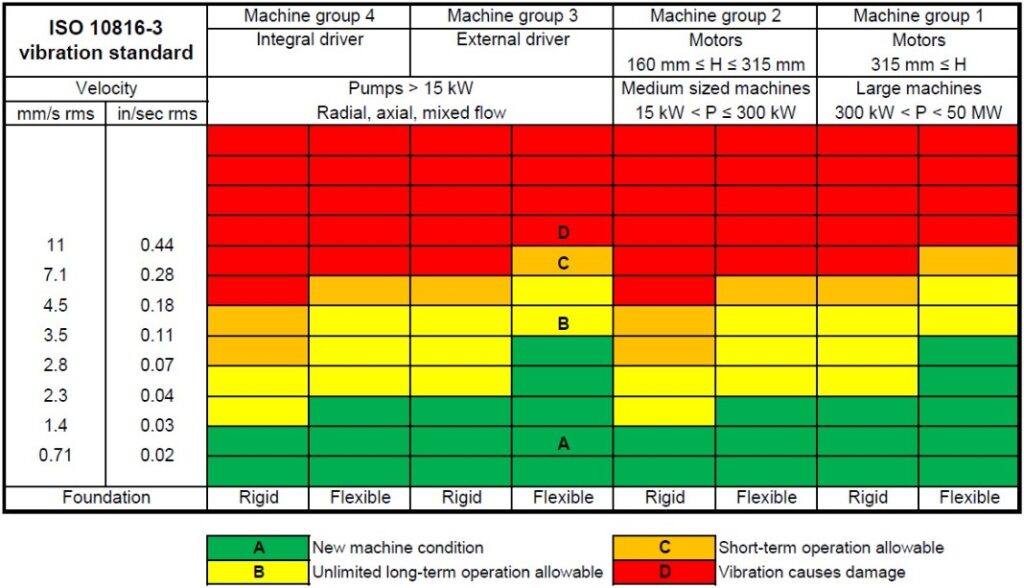

One of the most valuable aspects of ISO 10816-3 are guidelines on how best to interpret the results from vibration readings taken on non-rotating parts of the machine (such as the housing). The chart below provides a concise summary of how to interpret the severity of overall vibration readings based upon the machine group and foundation type.

Once readings are taken, the standard can be applied to evaluate if further action should be taken such as a more thorough diagnostic, operator check or specific maintenance activity to prevent equipment damage. It can also be a trigger to check the execution of standard preventative maintenance activities.

Applying the ISO 10816 Standard

Here is a common situation we see with our customers.

- Vibration monitoring programs are recognized as a valuable method for early detection of failure risk across various equipment types to prevent catastrophic failure, unnecessary repair costs and production downtime.

- Investments in continuous vibration monitoring solutions have been made in highly critical equipment which represent a small percentage of all rotating equipment.

- Expansion of vibration monitoring programs is desired on medium and low criticality equipment leveraging low-cost sensors and handheld devices.

The key challenge they face is how to leverage these new equipment condition data streams to their fullest potential without putting more burden on already stretched resources? Additionally, how to implement these new data streams without creating another siloed data source.

This is where enabling technology such as the Itus Asset Twin can be leveraged to develop best practices such as those that can be enabled with ISO 10816. With Itus technology, not only can the prescribed decision criteria be automated, but the results of the evaluation can also be driven into broader reliability and maintenance processes in your organization, realizing more value from your assets:

- Centralized management of all vibration monitoring advisories from your various sensors, field data collectors, and solutions to drive collaboration among your equipment experts.

- Integration of additional equipment conditions from other systems such as thermography, oil analysis, and process monitoring to enable broader failure mode coverage and overall asset health scoring.

- Automatic generation of requests in your maintenance management to drive appropriate follow up or repairs as needed.

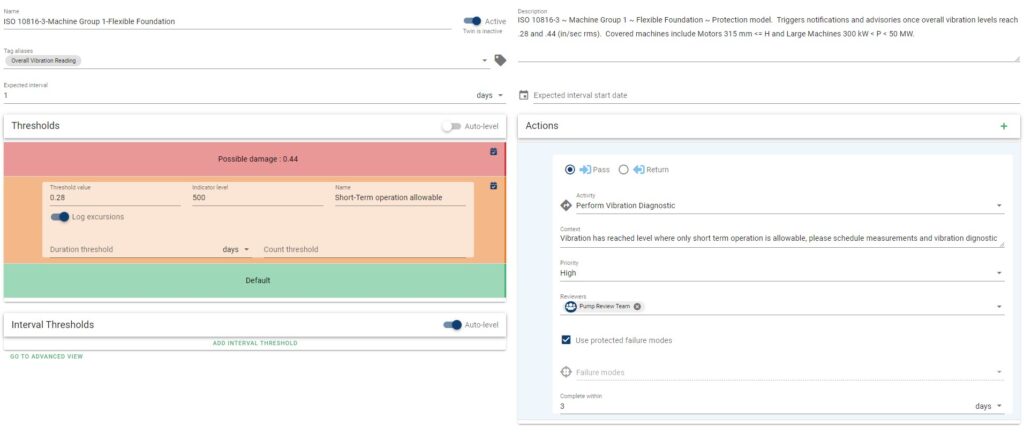

Let’s walk through a quick example of how ISO 10816-3 requirements are enabled with an Itus Asset Twin. Below is the configuration of the standard’s requirement for Machine Group 1 on a flexible foundation.

In this configuration, the Itus Asset Twin is utilized as a screening tool for machinery vibration to identify situations which require more diagnostic tests or the initiation of an inspect/repair activity. Here are the key aspects of the Protection implementation.

- Tag Aliases – The incoming vibration data stream from sensors, handheld devices or historians. This template is set up for readings with units of in/sec but mm/s is also supported.

- Thresholds – The definition for the analytical evaluation of the vibration readings. This example is very straightforward with two threshold evaluations, .28 in/sec and .44 in/sec.

- Actions – The prescribed action which will be recommended when the Threshold condition has been met. In this case, when the ISO defined Threshold of .28 in/sec is met we recommend performing a more detailed vibration diagnostic at a high priority within the next 3 days. If the vibration readings exceed .44 in/sec, we recommend an operations/maintenance intervention as the standard indicates the machine may experience damage.

This example of an Asset Twin demonstrates how ISO 10816-3 requirements can be technically enabled ‘in kind’ but you can easily adjust this definition based upon your specific operating experience and context as needed for your business needs.

Itus Libraries quickly enable the requirements of this standard

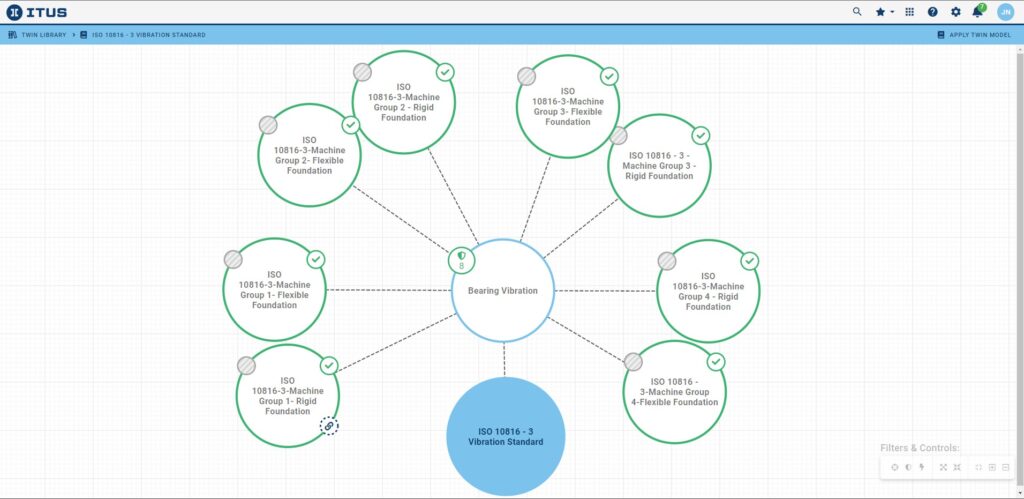

Our use case for this article has focused on one specific aspect of ISO 10816, Part 3, more specifically, machine group 1 with a flexible Foundation. Beyond this example, subscribers to the Itus solution have access to every scenario covered in Part 1 and 3 of ISO 10816 through the Itus Asset Twin Library. For subscribers of the Itus solution, the requirements of the ISO standard can be enabled for a piece of equipment within minutes by accessing the library, selecting the appropriate machine group and foundation type, and then applying the model to the vibration data feeds from sensors, devices or monitoring solutions.

The Itus Asset Twin Library also provides Asset Twin templates for the most common failure modes across over 200 types of industrial equipment. Leveraging this library allows maintenance and reliability teams to standardize their asset strategies and drive a consistent approach to preventive maintenance activities, condition monitoring and evaluation of equipment health.

Minimize failure risks by enabling standards requirements with Itus technology

Vibration monitoring is a very effective approach for early detection of potential failure in rotating machinery. Historically, applications of vibration monitoring have been limited to highly critical equipment due to the cost and required resources.

Advancements in sensor technology and handheld data collection have dramatically reduced the cost of assessing machinery vibration which now opens the opportunity to expand usage for medium and low criticality equipment.

The downside is organizations are now drowning in sensor data and need simple methods to analyze and interpret that data from a myriad of equipment and condition data sources. Fortunately, ISO 10816 provides a practical model to assess the severity of vibration readings and should be considered when implementing a vibration monitoring program.

Evaluation of vibration data and compliance to the ISO 10816 standard is just one simple use case of how the Itus APM solution can be used to drive optimal asset strategies to reduce maintenance cost and lower equipment failure rates. If you would like to learn more about our approach and solution, please connect with us here.